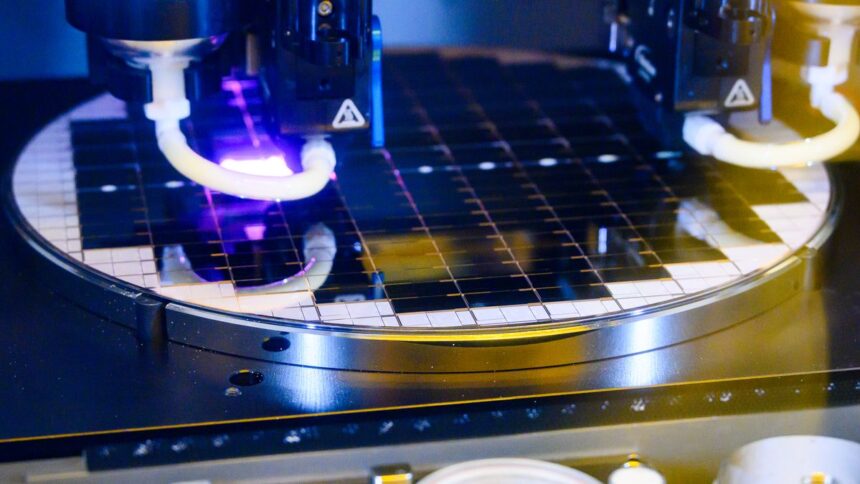

Intel’s future is heavily tied to the success of its new 18A manufacturing process, set to debut with the upcoming Panther Lake CPUs. While the company has publicly maintained that development is on track, fresh reports suggest otherwise.

According to sources cited by Reuters, only a small fraction of chips produced so far meet the quality standards required for consumer release. These insiders claim to have seen test data dating back to last year, showing persistent yield issues.

If accurate, this could pose a significant challenge for Intel, particularly in bringing Panther Lake to the mobile market, where production efficiency is critical.

Intel 18a Lithography Usage Index is low

Sources familiar with Intel’s production explain that the silicon yield rate is a moving target, and fluctuations in this metric can drastically alter key production data, which is exactly what has recently happened at the company.

Reportedly, Intel was aiming for a 50% yield before kicking off large-scale production. Starting manufacturing below that threshold could put pressure on profit margins. The same sources note that Intel generally avoids talking about profitability until yields hit at least 70–80%, the critical zone for high-end CPUs like Panther Lake.

Intel CFO David Zinsner told Reuters that yield rates “start low and improve over time,” adding that current performance trends give the company confidence in a successful launch that will reinforce its position in the notebook market.

Still, there’s uncertainty ahead. Intel has acknowledged that its 18A lithography might end up reserved for internal products if yield improvements stall. Moreover, future Foundry plans could be at risk — the company’s upcoming 14A process may be scrapped if it fails to attract enough customers.